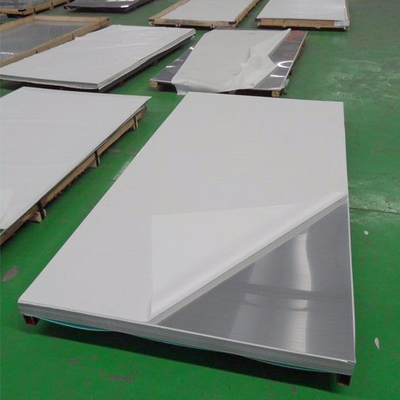

SS316/316L 2mmTHK Cold Rolled Stainless Steel Sheet plate ASTM A240/A240M No.4 Finished

The main performance of an SS316/316L 2mm THK cold-rolled stainless steel sheet plate with ASTM A240/A240M specification and a No.4 finish includes:

Corrosion resistance: SS316/316L stainless steel is known for its excellent corrosion resistance, particularly in environments with chloride exposure. The No.4 finish further enhances its corrosion resistance by adding a protective layer to the surface.

Surface finish: The No.4 finish is a brushed finish that provides a matte appearance to the stainless steel sheet plate. It has a uniform, linear grain pattern that hides fingerprints, scratches, and other surface imperfections, making it suitable for applications where aesthetics and easy maintenance are important.

Durability: SS316/316L stainless steel has high durability and strength, even with the No.4 finish. It can withstand wear, impact, and deformation, making it suitable for applications that require structural integrity and resistance to damage.

Formability: Cold-rolled stainless steel sheets, including those with a No.4 finish, have good formability. They can be easily bent, shaped, and formed into various configurations without compromising their structural integrity.

Heat resistance: SS316/316L stainless steel has good heat resistance and can withstand high temperatures without losing its strength or corrosion resistance properties. This makes it suitable for applications that involve exposure to elevated temperatures.

Easy maintenance: The No.4 finish of a cold-rolled stainless steel sheet is relatively easy to clean and maintain. Its brushed surface helps hide fingerprints and smudges, making it ideal for applications where a clean and neat appearance is desired.

Overall, an SS316/316L 2mm THK cold-rolled stainless steel sheet plate with an ASTM A240/A240M specification and a No.4 finish offers excellent corrosion resistance, durability, formability, heat resistance, and easy maintenance. It is suitable for a wide range of applications in various industries, including architectural, decorative, and industrial sectors.

| Carbon | ≤0.03% |

| Manganese | ≤2.00% |

| Phosphorus | ≤0.045% |

| Sulfur | ≤0.030% |

| Silicon | ≤0.75% |

| Chromium | 16.0%-18.0% |

| Nickel |

10.0%-14.0% |

| Nitrogen |

≤0.10% |

| Molybdernum | 2.00%-3.00% |

| Tensile Strength | ≥75ksi or ≥515MPa |

| Yield Strength | ≥30ksi or ≥205MPa |

| Elongation in 2inch,or50mm | ≥40% |

| Hardness | ≤217HBW or ≤95HRB |

![]()

![]()

![]()

FAQ:

Q1: What is the thickness of the SS316/316L cold-rolled stainless steel sheet plate?

A1: The thickness of the SS316/316L cold-rolled stainless steel sheet plate is 2mm.

Q2: What is the standard specification for this stainless steel sheet plate?

A2: The standard specification for this stainless steel sheet plate is ASTM A240/A240M.

Q3: What is the finish on the surface of this stainless steel sheet plate?

A3: The finish on the surface of this stainless steel sheet plate is a No.4 finish. A No.4 finish is a brushed finish that provides a matte appearance to the stainless steel. It has a uniform, linear grain pattern that hides fingerprints, scratches, and other surface imperfections.

Q4: What are the main properties of this SS316/316L cold-rolled stainless steel sheet plate with a No.4 finish?

A4: The main properties of this SS316/316L cold-rolled stainless steel sheet plate with a No.4 finish include excellent corrosion resistance, durability, formability, heat resistance, and easy maintenance. The No.4 finish enhances the material's corrosion resistance and provides a matte appearance that hides surface imperfections.

Q5: What are the common applications for this SS316/316L cold-rolled stainless steel sheet plate with a No.4 finish?

A5: This SS316/316L cold-rolled stainless steel sheet plate with a No.4 finish is commonly used in various applications, including architectural, decorative, and industrial sectors. It is suitable for applications that require corrosion resistance, durability, and a clean and neat appearance. Examples of specific applications include kitchen equipment, interior and exterior cladding, decorative trim, and industrial equipment.

Q5: What are the common applications for this SS304/304L hot-rolled stainless steel sheet plate with a 2B finish?

A5: This SS304/304L hot-rolled stainless steel sheet plate with a 2B finish is commonly used in various applications, including construction, automotive components, industrial equipment, and kitchen appliances. It is suitable for applications that require strength, corrosion resistance, and a clean and uniform appearance. Examples of specific applications include structural components, tanks, machinery parts, and food processing equipment.