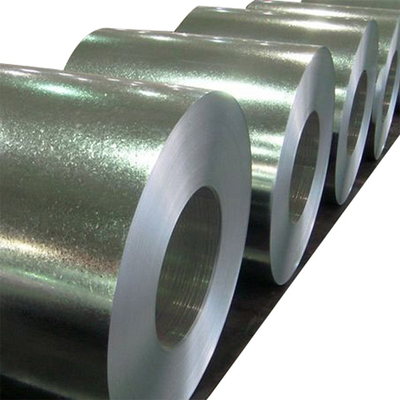

SGCC-Z12 0.4MM THK Galvanized Steel Coil JISG3302 Big Spangle

| Carbon | ≤0.15% |

| Manganese | ≤0.80% |

| Phosphorus | ≤0.05% |

| Sulfur | ≤0.05% |

| Zinc layer | ≥80g/㎡ |

| Tensile Strength | ≥270 MPa |

| Yield Strength | ≥205 MPa |

![]()

![]()

![]()

FAQ

Q: What is SGCC-Z08?

A: SGCC-Z08 refers to a galvanized steel coil with a zinc coating weight of 80 grams per square meter. SGCC is the designation for hot-dip galvanized steel in Japan, and the "-Z08" indicates the zinc coating weight.

Q: What is the thickness of the galvanized steel coil?

A: The thickness of the galvanized steel coil is 0.35mm, which refers to the thickness of the steel sheet before the galvanizing process.

Q: What is JISG3302?

A: JISG3302 is the Japanese Industrial Standard for hot-dip galvanized steel sheets and coils. It specifies the requirements for the mechanical properties, chemical composition, dimensions, and coating weight of galvanized steel products.

Q: What is zero spangle?

A: Zero spangle refers to the appearance of the zinc coating on the galvanized steel surface. It indicates that there are no visible zinc crystals, resulting in a smooth and uniform surface finish.

Q: What are the main properties of SGCC-Z08 0.35mm thick galvanized steel coil with zero spangle?

A: The main properties include corrosion resistance, strength, formability, and a smooth and uniform surface finish.

Q: What are the common uses of SGCC-Z08 0.35mm thick galvanized steel coil with zero spangle?

A: The galvanized steel coil with zero spangle is commonly used in various applications, including roofing, cladding, gutters, downspouts, ventilation ducts, and general manufacturing.

Q: Can a galvanized steel coil with zero spangle be painted or coated?

A: Yes, a galvanized steel coil with zero spangle can be painted or coated with various finishes for additional protection or aesthetic purposes. However, proper surface preparation and primer selection are important for achieving good adhesion of the paint or coating.

Q: Is the galvanized steel coil with zero spangle suitable for outdoor applications?

A: Yes, the galvanized steel coil with zero spangle offers excellent corrosion resistance and is suitable for outdoor applications where exposure to harsh weather conditions is expected. The zinc coating acts as a protective barrier against rust and corrosion.

Q: Can the galvanized steel coil with zero spangle be welded?

A: Yes, the galvanized steel coil with zero spangle can be welded using appropriate welding techniques and procedures. However, it is important to take precautions to prevent damage to the zinc coating during the welding process.